Details

Use

-

Exclusive use for undercut measurement

Material

-

Stainless steel

Features

- Easy and accurate to measure depth and length of undercut

- Dial gauge type performs more precise measurement

- Three point support for stable measurement

Specifications

- Measuring Range: 0~4.00mm

- Minimum reading: 0.01mm

- Accuracy: ±0.04mm

- Width of measurement base: ≒ 23mm

Weight: 280g

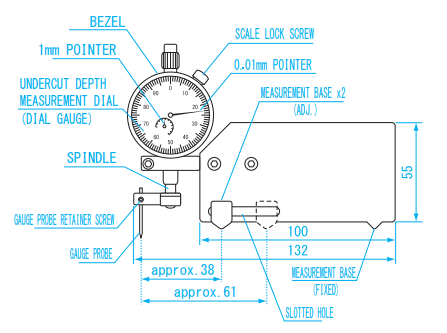

Dimensions ( Unit: mm)

Zero Adjustment

Recommended to be performed on a flat surface such as a surface plate

(1) Loosen GAUGE PROBE RETAINER SCREW using hex key

(2) Place Welding Gauge on surface insuring all three points of

MEASUREMENT BASE are making contact (2x ADJ, 1× FIXED) and push on SPINDLE shaft. When 1mm POINTER indicates 4.00mm, tighten GAUGE PROBE RETAINER SCREW. (Insure that probe tips in contact with we surface plate)

Measurement

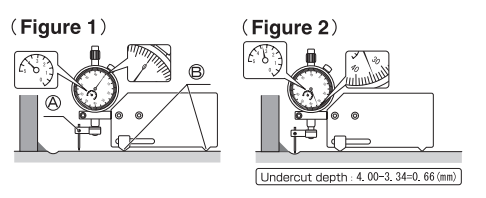

1 Place the gauge on a flat surface and rotate BEZEL to indicate 0.01 mm. (Figure 1)

(2) Place PROBE tip on weld undercut point to be measured. (Figure 2)

(3) Undercut value is obtained by subtracting Dial Gauge reading from 4.00mm

View more about Niigata Seiki FDW-1 Welding Gauge on main site